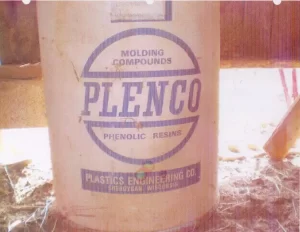

Asbestos in Plastics: Unraveling Health Risks in Molding Processes for Workers

Asbestos-molded plastic products had applications in electrical components, consumer goods, textiles, automobile parts, aircraft, weapon systems, and construction materials.

Workers inhaled asbestos dust when opening bags of plastic molding compound, and the molding process itself generated additional dust. Finishing processes, such as tumbling and hand-filing, further exposed workers to asbestos dust. This occupational exposure to asbestos in molded plastic compounds has been linked to serious health issues, including mesothelioma and lung cancer.

Products used by plastics workers that may contain asbestos include but are not limited to:

- Electrical switches

- Circuit breakers

- Arc chutes

- Brake pad linings

- Distributor caps

- Coils

- Aircraft weapons systems

- Missile casings

- Epoxy

- Resin

- Hardeners

- Pastes

- Sealers

- Panels

- Compounds

- Boards

- Cement

- Sheets

- Molding compounds

- Molding boards

- Coatings

- Lacquers

- Adhesive putties

- Cloth

- Liquids

- Fillers

- Glues

Industries We Represent

Michigan Unions And Trades We Represent

Endorsed by Plumbers Local 98